I designed and assembled a custom quadcopter drone to minimize cost while achieving stable flight and reasonable performance. In this project, I focused on understanding the principles of aerodynamics, motor and propeller selection, electronic speed control, flight stabilization algorithms, and structural optimization. The system needed to be constructed from readily available, affordable components and provide sufficient lift, controllability, and durability. This required thoughtful trade-offs at each stage of design.

Frame and Structural Integration

The drone’s foundation was an F450-class frame, measuring approximately 450 mm diagonally from motor to motor. The frame’s main plates and arms typically consisted of glass-fiber or reinforced nylon, providing moderate stiffness and impact resistance. To improve durability and aesthetics, I added custom ABS 3D-printed protective structures. These were attached using existing frame standoffs and standard fasteners, ensuring protection for internal electronics and mitigating damage during minor crashes. The ABS prints had moderate infill and carefully chosen wall thicknesses to balance weight and strength. Overall, the assembled platform had an 800–1000 g mass, including motors, electronics, protective panels, and batteries.

Propulsion and Power Systems

Four 2212 brushless DC motors with a 1400 KV rating were selected based on typical usage for F450 frames and their ability to provide stable lift. These motors were paired with 10x4.5-inch propellers, a standard configuration known to produce sufficient thrust for this class of airframe. Each motor was controlled by a 30A electronic speed controller (ESC). These ESCs, commonly available and pre-loaded with standard firmware, were individually calibrated to ensure uniform throttle response.

A three-cell (3S) LiPo battery, rated at 1500 mAh, was chosen as the power source. This capacity offered approximately 5–7 minutes of flight time under moderate throttle settings. Mounting the battery near the frame’s geometric center maintained the proper center of gravity, an essential factor for stable flight. Limited payload capacity meant careful distribution of onboard components, ensuring that the drone remained well-balanced and responsive.

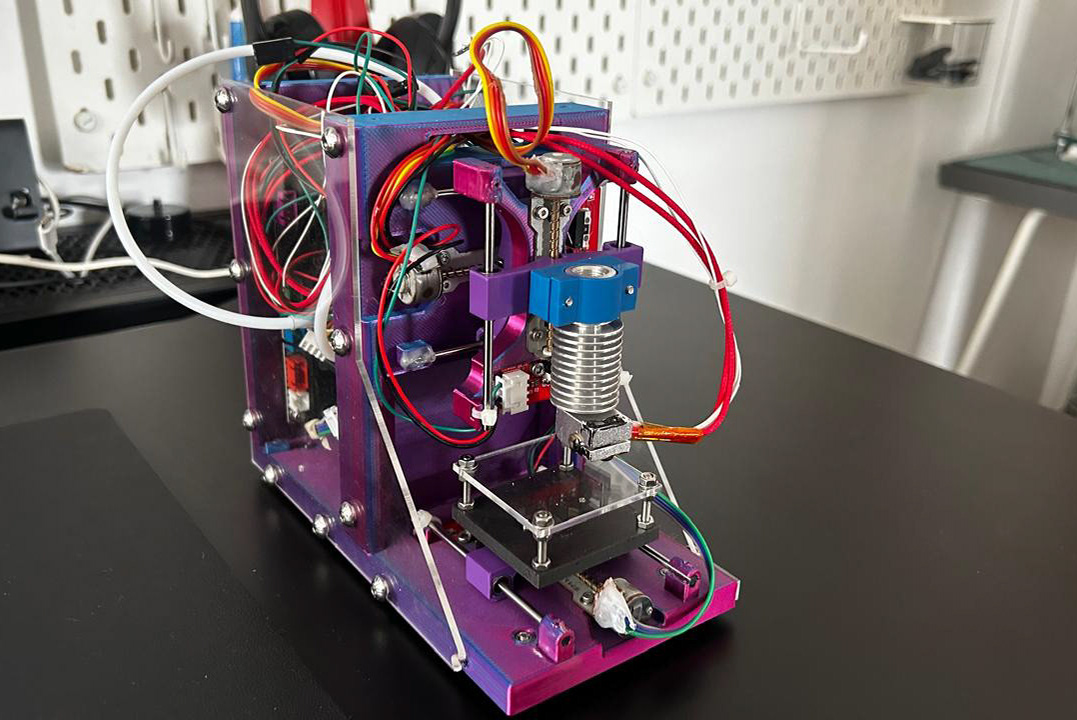

Flight Control and Electronics Integration

At the core of the flight control system, an Arduino Uno acted as the primary processing unit. It interfaced with an MPU-6050 IMU (Inertial Measurement Unit), providing gyroscopic and accelerometric data. The Arduino ran a custom flight stabilization algorithm incorporating a basic PID loop. The Arduino interpreted signal inputs from a six-channel receiver linked to a standard low-cost transmitter, which then adjusted motor outputs to maintain a stable attitude and respond to pilot commands.

This approach circumvented the need for specialized commercial flight controllers, significantly reducing costs while increasing educational value. Students and users could directly modify the code or experiment with PID tuning, gaining insight into flight dynamics, control theory, and the role of sensor data filtering. Although this solution required additional programming effort, the result was a more accessible and instructive platform.

Testing and Validation Procedures

Bench tests were conducted before initial flights to verify motor speed ranges, current draw, and thrust generation. A wattmeter and tachometer were used to measure electrical and mechanical parameters, ensuring that component choices aligned with expected performance targets. After confirming that the system’s electronics functioned reliably, trial flights were performed in calm outdoor conditions to assess hover stability and response to control inputs. ESC calibration and PID parameters were adjusted incrementally to achieve smooth handling and predictable maneuverability. Multiple takeoffs and gentle landings verified the durability of the ABS protective components and the frame’s ability to withstand minor impacts.

By constructing this drone, I acquired practical experience in selecting and integrating cost-effective propulsion, control, and structural systems. I learned how to balance motor KV ratings, propeller sizes, and battery capacities to achieve stable flight times and manageable control authority. Implementing an Arduino-based flight controller and IMU sensor provided hands-on opportunities to understand flight stabilization algorithms' fundamentals and sensor feedback's importance.

For future enhancements, more advanced closed-loop control algorithms, refined PID tuning methods, or upgraded sensors could improve flight precision. Experimentation with lighter materials or modular frame components could reduce weight, increasing flight duration and responsiveness. Additionally, introducing systematic testing protocols would enhance reliability and provide deeper insights into flight efficiency, guiding subsequent design iterations toward more capable and versatile UAV systems.